Top 10 Solar Project Solution Factory In China

Background of the project:

1. A new project for a snow cleaning equipment factory in Japan

2. Product upgrade, use high-power snow removal equipment to improve snow removal efficiency

3. Take advantage of the new energy debate and save money.

client needs:

1. High quality inverter products.

2. must pass the factory inspection before placing the sample order

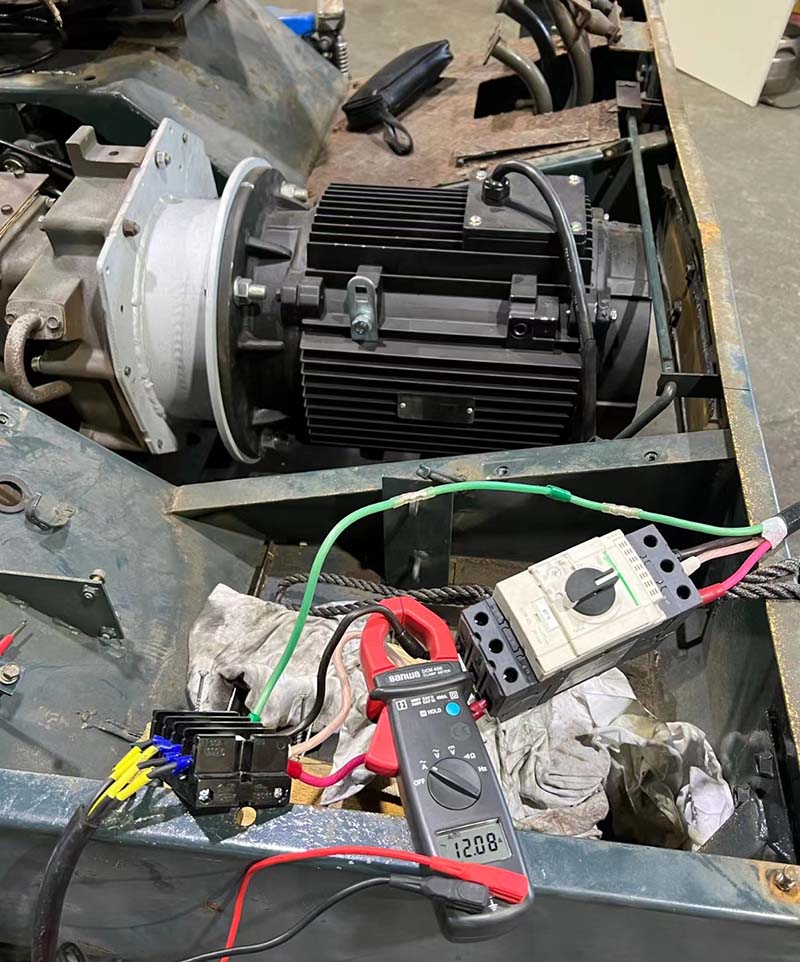

3. Carry his 18KW equipment, which is more convenient

Design:

1. Because his snow removal equipment is an inductive load, the starting power is 2-3 times, so choose 40KW inverter copy is used.

2. Japan has no neutral wire, so it is 440V, L+L+L+G design

3. Conventional test voltage 360V

Realize the effect:

1. For convenience , the customer used a small battery of 75AH for testing, but it could not bring the equipment. After communication with the engineer, he replaced the battery with a 150AH, and 40KW can drive his 18KW equipment.

2. In order to save costs, we will continue to test 20KW and 30KW inverters to carry the load.

3. Through rigorous and repeated testing, I believe it will give customers a better and more cost-effective solution copy.