Top 10 Solar Project Solution Factory In China

The solar cells are cut into 5 or 6 cells, and each small cell is superimposed and arranged, and the small cells are connected into a string with conductive glue, and then laminated into a module after series-parallel layout.

1). The shingled components of the same area can be packed into more cells.

The conductive glue is used to connect the cells to achieve zero spacing between the cells, which greatly reduces the white space of the package. Using shingled technology can encapsulate 66 batteries, which brings a 10% increase in power.

2). Shingled components generally the cell slice is cut into 5 or 6 slices, so that the current of the monolithic battery is only 1 /5 or 1 /6 of the original current consumption and the current consumption is only the original 1/25 or 1/36,which has lower resistance compared to the use of solder ribbon , Low power loss.

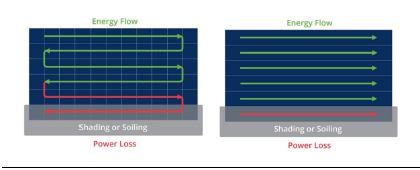

One the left, it is the traditional panel, the cell slice is connected in series, If have the shading, the whole panel could not produce the power.

One the right, it is this Shingled panel, the cell slice is connected in parallels. If have the shading, only the covered part don’t produced power, don’t affect the whole panel.

So the shingled panel can effectively reduce the loss of power generation and hot spots caused by shading.

2). Longer Warranty time

Shingled panel is 15 years warranty, the other panels are 10 years

USA TR Technology,increase module efficiency, mono-facial up to 21.88%

Strong anti-cracking advantage

4).Power increase 10% or more

Theoretically, the power of watts can be increased by 15%, and the power of mass production can generally be increased by 10%- 12%. Based on M 2 specification, for mono PERC cells, the power of 60-type conventional monolithic module can reach 315W, while the shingled one can reach 345W!

Table One: Comparison of solar panel power with different assembly methods (unit: w)

|

Regular whole piece |

Half cell |

Helf +MBB |

Spliced piece |

shingled |

|

315 |

320 |

325 |

330 |

345 |

At present, the double and triple IEC test attenuation of shingles meets the requirements of IEC, especially according to the test result of Seraphim CNAS laboratory after TC600, the attenuation is only 1.03%. Better than conventional components.

Tanfon solar always keeps up with the trend of technological development and provides you with the latest technological products!Welcome to contact with us.

The King of the Democratic Republic of the Congo has provided a solar energy storage power station system for the village of Bunkeya to meet the electricity needs of 2500 small households in the village. As the village currently lacks access to the grid, the King requested the design of a 1MW solar panel system paired with a 1.8MWh lithium battery storage system to power the entire village.