Top 10 Solar Project Solution Factory In China

Will the color difference of PV modules affect the life and power generation?

First, why the components are inconsistent in color

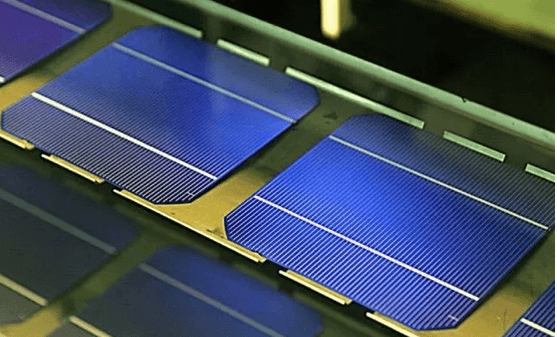

The color of the solar cell is actually mainly affected by the texturing.

The red film is mainly caused by the low amount of texturing corrosion. If the amount of texturing corrosion is less than 3, the damaged layer of the silicon wafer will be removed incompletely, resulting in a reddish color after the PE coating.

The so-called flower piece is caused by the excessive amount of corrugated corrosion. In general, when the amount of texturing corrosion is higher than 4.5, the silicon wafer is equivalent to the polishing treatment, and the cell after the coating is bright, and the grain boundary is also More obvious.

For yin and yang tablets, there are two cases:

One is the immersion situation;

Second, there is a deviation in the amount of corrosion between the roads;

The problem of immersion liquid is caused by the horizontal level of the front and rear rollers and the front baffle during the production process. When the silicon wafer enters the velvet tank, there is a time difference between the contact of the liquid and the silicon wafer. In this way, the amount of corrosion in the area where the silicon wafer first contacts the chemical solution is bound to be higher than the area in which the liquid is contacted later. The difference in the amount of corrosion inevitably leads to inconsistent suede effect on the surface of the silicon wafer, and a certain color difference will occur after the PE coating. In order to ensure the effect of immersion, it is necessary to adjust the flanking roller and the baffle.

The common color deviation is polycrystalline silicon cells. For polycrystalline silicon cells, dark blue is the most common color, and single crystal silicon is black.

Through the process adjustment, the above color deviation problem can be effectively solved.

Second, qualified photovoltaic modules also have color difference

Because of the use of coated glass, this can hardly be avoided with the use of coated glass. The same batch of coated glass does not show any difference between the factory and the incoming inspection, and even can not be seen after the assembly, only after installation, can be found under certain angles and illumination.

Another possibility is the hydrophilicity of the glass. When we tested it, we found that the coated glass of different manufacturers has different hydrophilicity. When it encounters rain or fog or dew, the difference is quite big, so the components appear. The phenomenon of different colors. Under normal circumstances, the component has a slight color difference is normal, but if there is a variety of colors on a board, there is a problem with the quality of the product.

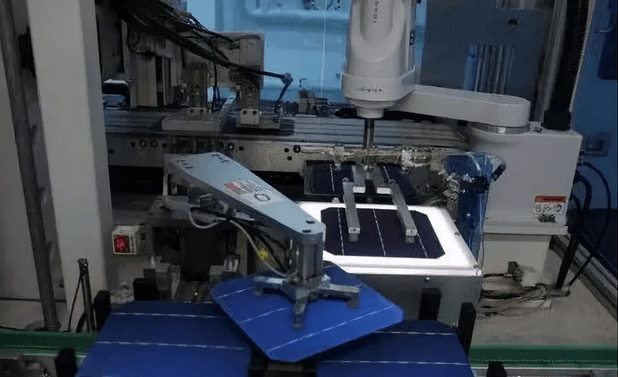

When the general PV products are shipped from the factory, each component has undergone rigorous inspection and can be used with confidence.

3. Does chromatic aberration affect power generation and life?

The use of PV arrays with inconsistent colors will affect the overall appearance, and customers are not psychologically acceptable. The simple color difference of PV modules will not affect the power generation and life. The factors affecting the power generation are mainly hard injuries, such as cracks, and the color difference is only a process problem, so it does not affect the power generation and life of PV modules.

The King of the Democratic Republic of the Congo has provided a solar energy storage power station system for the village of Bunkeya to meet the electricity needs of 2500 small households in the village. As the village currently lacks access to the grid, the King requested the design of a 1MW solar panel system paired with a 1.8MWh lithium battery storage system to power the entire village.