Top 10 Solar Project Solution Factory In China

| Why choose TANFON inverter | |||

| TANFON | Others | ||

|

TANFON pure sine wave inverter promise full KW capacity output, Have service evidence to choose us to be safer |

Other inverters High repair rate, short time stabilization |

||

|

|

|

|

|

Core: An individual 64-bit DSP control chip, more test sample and control functions The detection and control program is written into the DSP chip. The results are fetched by DSP chip and the inverter is controlled by DSP chip. The advantage is that the value is accurate (by effective value). Tolerance is less than 0.01%. |

Other inverter in the market are controlled by hardware circuit. Disadvantages: 1. Components will have the ageing problems. 2. Complicated production processes, full of wires,which will raise not only the manual defects during production and after sales problem, but also the cost of maintainance. |

||

|

|

|

|

|

Photoelectricity isolation circuitry technology(more stable): It can detect and modulate the pulse width of boost circuit, reduce the EFT (electric fast transient) and raise anti-interference. |

Other inverter without this function, which will cause high EFT (electric fast transient) and low anti-interference. |

||

|

|

Other inverter without this function: |  |

|

Switching power is supplied by independent system |

When inverter is in normal use, the consumption of the switching power supply chip is large. If directly use resistance for voltage reduction, it can easily lead to unstable. |

||

|

|

|

|

|

Ture over Temperature protection Built-in realtime temperature monitoring probe can truly detect the inside temperature of inverter and transmit the data to the DSP intelligent chip in order to analyse the results of temperature. |

Through detection of the loading situation of inverter by circuit . NTC: Loading is small but temperature of environment will also affect the life of inverter during use. so it can't protect the inverter properly in this way. |

||

|

|

|

|

|

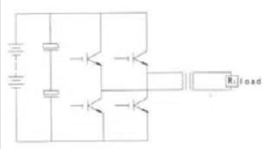

Full-bridge rectifier and PCB structure is highly optimized. input and output circuits are truly isolated. PCB is highly optimized,which is insulated and isolated by modularization. Full-bridge front-end circuit rectifies and provides outputs, back-end circuit transformer controlled by intelligent program.input and output circuits are truly isolated. And model number production date and batch. |

PCB circuits are not actually insulated and isolated by modularization. input and output are not truly isolated. Problem caused by either input or output will damage the inverter. |

||

|

Stron loading capacity Which provides the true onetime soft start. Helped by the highly optimized circuit structures,original electronic components and high-tech DSP program,full range of all our models can achieve maximum power loading by only onetime soft start. 3000W=3000W 5000W=5000W |

Due to the limitations of hardware and software technology, the loading way is gradually increasing. For example, to start a 1000w loading: other inverter requires 200W+300W+500W to superimpose the loading to 1000W |

||

|

|

|

|

|

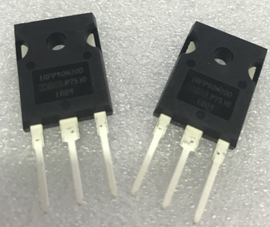

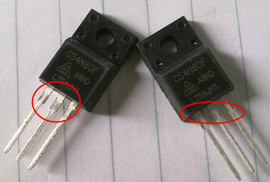

Original electronic components TANFON: NEW and original electronic components are used for internal parts including capacitors, resistors, transformers, Mosfets, we import U.S. brand infineon IR MOSFETs with certificate of origin. batch and date of production, which guarantees original and high quality. |

Other: Most of inverters in the market use second hand and disassembled parts from export, especially MOSFETs and capacitors. The problem of second hand and disassembled parts is that they are disassembled from old used appliances, which will cause poor contact. |

||

|

|

|

|

|

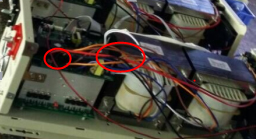

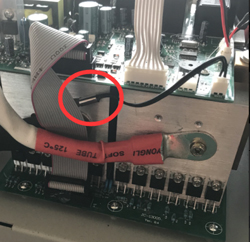

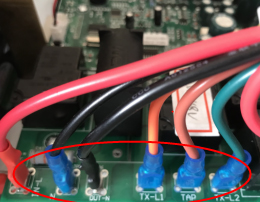

Plug-pull posts are used for internal circuit lines and signal lines Internal PCB wires either circuit connection or signal cables are all plug-pull post.Laborers only need to plug wires into relevant post during production, no need for manual welding, which highly reduces labor fault rate |

Other: Internal wiring is complex and chaotic, it needs manual welding. Laborer will easily make mistakes which leads to high fault rate, and also especially for oversea customers, they can't achieve fast and effective after sales service without professional team of electric engineering and repair. |

||

|

|

|

|

|

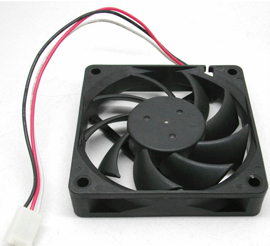

Dual ball bearing intelligent cooling fan: Through built-in realtime temperature monitoring probe it can speed up or slow down according to the working temperature of inverter, in order to reduce the consumption of power.sand proof design, to keep cooling fan works properly in outdoor environment |

Temperature is detected by circuit NTC (Negative temperature coefficient), it can only control the on/off function of cooling fan, which is not true intelligent cooling fan. |

||