Top 10 Solar Project Solution Factory In China

| Solar Panel | ||

| System | System Essentials | Pictures |

|

Supply System |

1. Solar cell: Dark color, black, no color difference 2. Solar Cell shape: corner piece 3. Solar cell efficiency: 21% |

|

|

Production System |

1. Classification of solar cell with different colors, powers and efficiencies using automatic sorting equipment 2. EL test of the solar cell by EL device to ensure that the solar cell is not cracked 3. Components are fully automated production line operations |

|

| QC System |

1. EL tester tests the solar cell to ensure no cracks 2. The component tester performs EL and data testing before component packaging to ensure data is acceptable and components are not cracked. 3. Component products are monitored with data from a tester to ensure data is correct |

|

|

Packaging System |

1. Can be packed in carton box or wooden cases 2. The solar panel is in an upright packaging mode to reduce the transport breakage rate |

|

|

Factory Inspection System |

QC inspection qualified products, distinguish the identification zone placement, ensure the shipment quantity, model, customer name is correct. | |

| After Sales Service System | Free replacement of new solar panel during the 10-year warranty period if have any quality problem. | |

Solar panel production video: Classification of solar cell with different colors, powers and efficiencies using automatic sorting equipment

| Solar Inverter | ||

| System | System Essentials | Pictures |

|

Supply System |

1. Since the establishment of our inverter factory, we have been purchasing transformers and capacitors from the same supplier. 2. MOS tube adopts imported IR brand 3. SCR adopts imported from Germany 4. IGBT adopts Japanese Mitsubishi brand |

|

|

Production System |

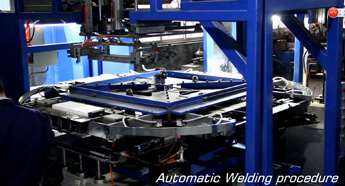

Wall-mounted inverter board production uses automated machine plug-ins. Improve efficiency, reduce loss, and enhance stability |  |

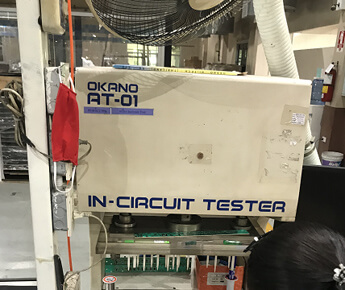

| QC System | ICT test, pinhole alignment PCB board, check all lines, reduce the failure rate. |  |

|

Packaging System |

Power lower than 1KW inverter carton packaging, containing pearl cotton; power higher than 2KW inverter plywood wooden box packaging, containing pearl cotton. One piece one packaging. |  |

| Factory Inspection System | Our inverter has passed 100 times of ultimate power-off test. According to statistics, 99% of the tested inverter can work very stable. |   |

| After Sales Service System | All inverters are free to send new spare boards within the warranty. For more services, please click the link to view. | |

Solar inverter board production: use automated machine plug-ins. Improve efficiency, reduce loss, and enhance stability

| Solar Battery Gel Battery | ||

| System | System Essentials | Pictures |

|

Supply System |

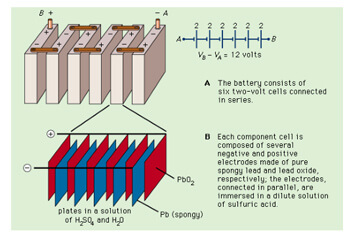

1. Battery case, ABS material conforming to UL94HB and UL94V-0 standards, no color difference, no crack. 2. The unique lead-calcium grid improves the hydrogen evolution potential, reduces gas evolution, reduces corrosion rate, and extends battery life. 3. The use of copper terminals, excellent conductivity and high wear resistance, enhances high current discharge performance; 4. High quality AGM partition for partition

|

|

|

Production System |

1. Battery plate production workshop, independent production of positive and negative plates, effectively ensuring the quality of the plates 2. Semi-automatic cladding machine): Semi-automatic double-layer cladding technology, double-layer separator can better prevent short circuit of the pole plate. The semi-automatic double-layer board process ensures that the packaged groups are neat, beautiful and clean. 3. Automatic slotting machine: higher efficiency, saving the process involved in manual slotting, avoiding the human contact group, maximizing the protection of the pole group, making the battery have very good self-discharge performance, battery consistency, total Voltage consistency.

|

|

| QC System |

1. DC spectrometer: high precision detection of lead purity to ensure purity above 99.994% 2. High current detector: ensure that each battery is under high current, whether charge and discharge normal 3. Large battery tester: Under high current, whether the bus bar of the battery has a problem of melting and short circuit 4. Internal resistance meter: Make sure that the internal resistance and voltage of each battery are normal, and the consistency of the battery.

|

|

|

Packaging System |

Carton packaging, use the inspection-free pallet to hold the shipment |  |

| Factory Inspection System |

QC inspection qualified products, distinguish the identification zone placement, ensure the shipment quantity, model, customer name is correct |

|

| After Sales Service System |

Free replacement of new batteries during the 2-year warranty period if have any quality problem |

|

The King of the Democratic Republic of the Congo has provided a solar energy storage power station system for the village of Bunkeya to meet the electricity needs of 2500 small households in the village. As the village currently lacks access to the grid, the King requested the design of a 1MW solar panel system paired with a 1.8MWh lithium battery storage system to power the entire village.